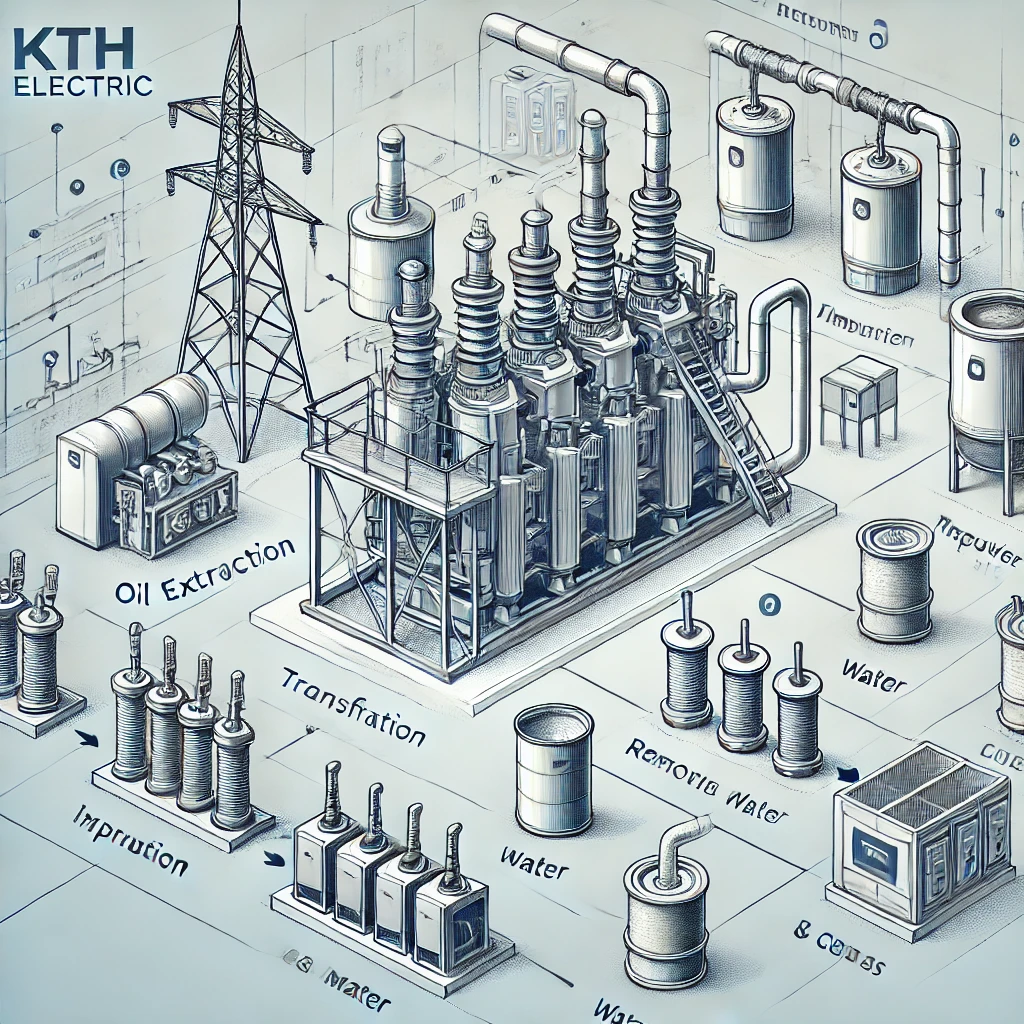

Transformer Oil Filtration Service

Transformers are the heart of any electrical system, and insulating oil is a crucial factor in determining their performance and durability. Over time, however, insulating oil can become contaminated with impurities, moisture, or dissolved gases, reducing its dielectric properties and increasing the risk of failure. The Transformer Oil Filtration Service from KTH ELECTRIC provides an optimal solution to ensure your transformers operate efficiently and reliably.

Why Is Transformer Oil Filtration Necessary?

Insulating oil not only provides insulation but also cools transformers during operation. However, insulating oil is prone to aging and contamination, leading to serious issues:

- High water content: Reduces insulation capacity, increasing the risk of short circuits.

- Dissolved gases: Decreases insulation efficiency and raises operational temperatures.

- Impurities: Blocks oil flow, impacting cooling performance.

Without regular filtration, transformers can face severe failures, resulting in high repair or replacement costs.

Benefits of Regular Transformer Oil Filtration

- Improves dielectric performance: Removes impurities and moisture, ensuring optimal insulation standards.

- Extends equipment lifespan: Prevents damage and reduces component replacement costs.

- Ensures safety: Avoids electrical failures that disrupt operations.

- Cost savings: Regular maintenance minimizes risks and long-term operational costs.

Transformer Oil Filtration Process at KTH ELECTRIC

| Step | Task Description |

|---|---|

| Survey and Assessment | Measure BDV, water content, and dissolved gases to determine the current oil condition. |

| Filtration Process | Use high-capacity filtration machines to remove impurities, gases, and water, ensuring oil quality. |

| Post-Filtration Inspection | Evaluate oil quality after filtration to ensure insulation standards are met. |

| Handover and Acceptance | Provide detailed reports and periodic maintenance advice to sustain transformer performance. |

Types of Insulating Oil and Required Standards

| Type of Insulating Oil | Characteristics |

|---|---|

| Mineral Oil | Commonly used in traditional transformers. |

| Synthetic Oil | Highly durable, withstands extreme temperatures and conditions. |

Key Standards:

- BDV (Breakdown Voltage): > 70 kV.

- Water Content: < 3 ppm.

- Dissolved Gas Content: < 0.5%.

- Purity Level: ≤ 1 µm.

Modern Equipment and Technology for Oil Filtration

High-Capacity Filtration Machines

- Filtration capacity of up to 3000 liters/hour, suitable for large transformers.

- Effectively removes impurities, gases, and water, meeting insulation standards.

Advanced Filtration Technology

- Gas and Water Removal: Protects the dielectric performance of the oil.

- IoT Integration: Enables real-time monitoring, optimizing operations and maintenance.

When to Perform Transformer Oil Filtration or Replacement?

- Signs of Oil Degradation:

- Color changes, cloudiness, or darkening of oil.

- BDV below standard levels.

- Unusual odor or signs of oxidation.

- Recommended Frequency:

- Once a year for transformers in normal conditions.

- Every six months in high-temperature or humid environments.

- Consequences of Delaying Filtration:

- Reduces transformer lifespan.

- Increases the risk of electrical failures and repair costs.

Why Choose KTH ELECTRIC for Transformer Oil Filtration?

- Modern Technology: Utilizes advanced filtration machines for top-tier performance.

- Experienced Team: Over 10 years of expertise delivering professional and dedicated services.

- Comprehensive Service: Includes inspection, oil filtration, replacement, and regular maintenance.

- Post-Service Support: Offers detailed reports and advice for continuous monitoring of equipment.

Learn more about our Online Partial Discharge Testing Service.

Contact KTH ELECTRIC Today

KTH ELECTRIC is committed to providing comprehensive transformer oil filtration and maintenance solutions to help customers optimize their electrical systems.

📞 Hotline: 0968 27 1199

📧 Email: info@kth-electric.com

🌐 Website: kth-electric.com

Let us help you protect your electrical systems efficiently and sustainably!

Tiếng Việt

Tiếng Việt