Knowledge

Recloser Classification 2025: Interrupting Mediums & Controls

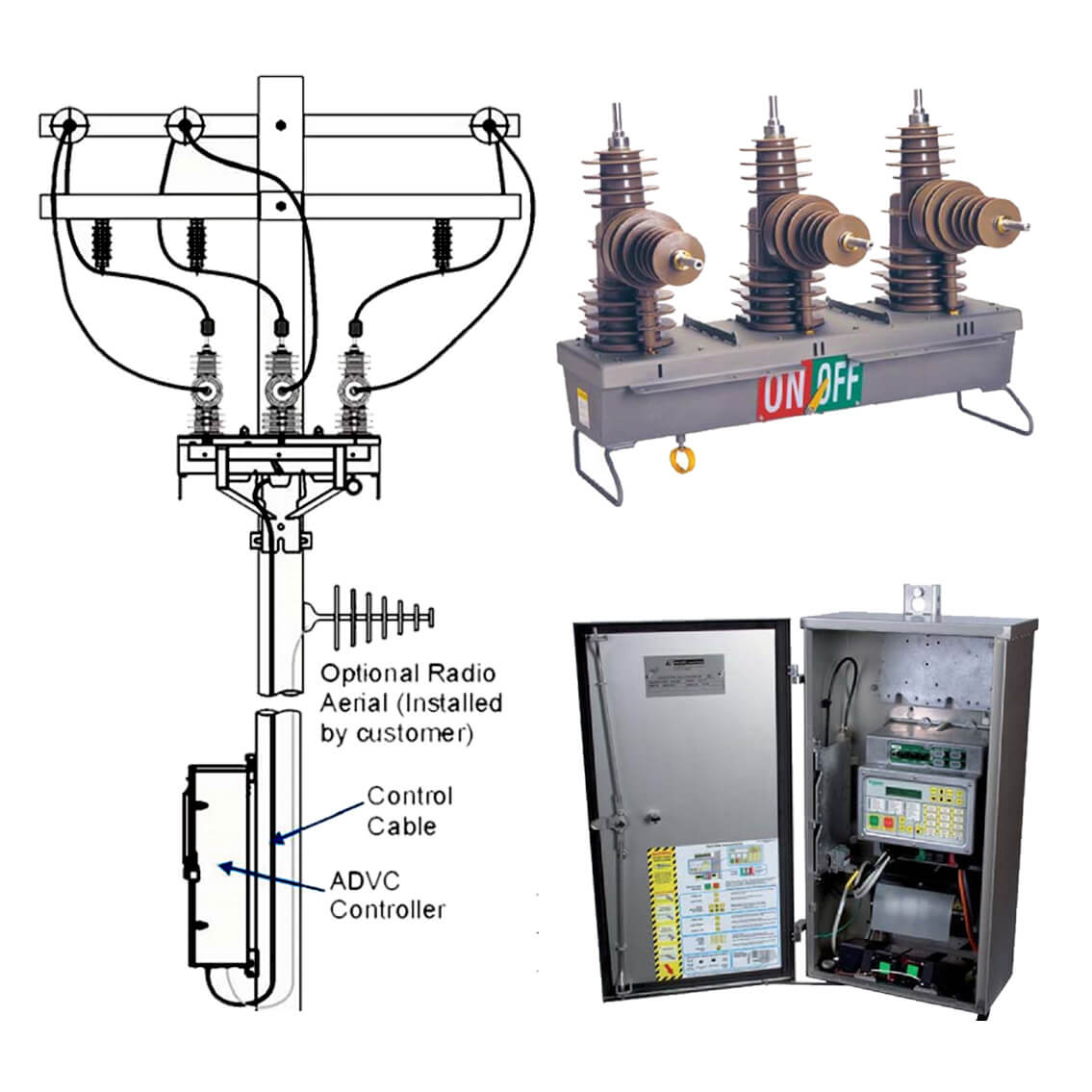

TECHNICAL GUIDE: RECLOSER CLASSIFICATION BY INTERRUPTING MEDIUM & CONTROLS (2025)

1. Classification by Interrupting Medium

Understanding the interrupting medium is essential as it dictates the Operations & Maintenance (O&M) schedule and the equipment’s lifecycle. The shift from oil to vacuum technology represents the most significant evolution in medium-voltage distribution equipment.

A. Oil Interrupters

This is the traditional technology where oil serves a dual critical role:

- Function: It is used to quench the electric arc generated during circuit interruption AND acts as the basic insulation medium.

- Mechanism: Some reclosers with hydraulic controls utilize the pressure of this same oil for timing and counting functions.

- Operational Drawback: Oil degrades over time and with the frequency of interruptions. This necessitates regular oil sampling, filtration, or replacement, resulting in higher O&M costs and potential environmental hazards from leakage.

B. Vacuum Interrupters

This is the modern industry standard for medium-voltage distribution.

- Speed: Provides fast, low-energy arc interruption (typically within 1-3 cycles).

- Longevity: Contact and interrupter life far exceeds that of oil media, often lasting the life of the pole mechanism.

- Safety: Minimizes fire risks associated with oil pressure buildup.

- Mechanical: Reduces mechanical stress on moving parts due to shorter travel distances.

Insulation Note: While the arc is quenched in a vacuum bottle, the external insulation medium (ensuring phase-to-phase and phase-to-ground isolation) can vary:

- Oil

- Air

- Epoxy (Solid Dielectric) – Current trend for maintenance-free operation.

2. Control Systems

The control unit is the “brain” of the recloser, determining grid reliability.

Electronic Controls

Electronic controls have been widely deployed since the mid-1980s (e.g., the Eaton Form 7 series) and remain prevalent in many grids today.

Technical Features:

- Offer programmable protection settings (overcurrent, earth fault, sensitive earth fault).

- Event logging capabilities to assist in post-fault analysis.

- Integration with SCADA for Smart Grid automation and remote switching.

Current Status: While many electronic controls from the 80s and 90s are still operational, the industry is shifting toward microprocessor-based relays for advanced diagnostics, though the fundamental electronic logic remains valid.

3. Quick Technical Comparison Table

| Feature | Oil Interrupters | Vacuum Interrupters |

|---|---|---|

| Arc Quenching Principle | Uses oil energy/pressure | Uses vacuum environment |

| Maintenance | High (Oil changes, filtration) | Low (Interrupter is sealed) |

| Contact Life | Moderate | Very High |

| Safety Risks | Fire risk (if oil degrades/leaks) | Minimal risk |

| Typical Application | Legacy grids, rural areas | Modern grids, urban areas, Substations |

4. Operational Recommendations (Actionable Steps)

If you manage a grid containing both technologies, implement the following:

- For Oil Reclosers: Establish a strict maintenance schedule (every 6-12 months) to test dielectric breakdown voltage and oil levels.

- For Vacuum Reclosers: Focus inspection on the mechanical linkage and the external insulation (bushings/tank), as the vacuum bottle itself rarely fails.

- Upgrade Strategy: If you are using legacy hydraulic controls, consider a Control Retrofit. You can upgrade to an electronic control (like the Form 7 or newer) to gain remote monitoring capabilities without replacing the entire recloser tank.

Mr. Đỗ Tấn Tuấn oversees all content on the kth-electric.com website. Each article is crafted from his extensive expertise, combining reputable reference materials (with specific citations) and his vast practical experience. Readers can fully trust the accuracy and reliability of the information, ensuring that every shared piece of content provides valuable and trustworthy insights.

Tiếng Việt

Tiếng Việt