Busway System Maintenance – Comprehensive Solutions by KTH ELECTRIC

Busway Maintenance Solutions from KTH ELECTRIC

Protect your busway system today! KTH ELECTRIC offers comprehensive maintenance solutions to ensure optimal performance and safety for your plant and high-rise building electrical systems.

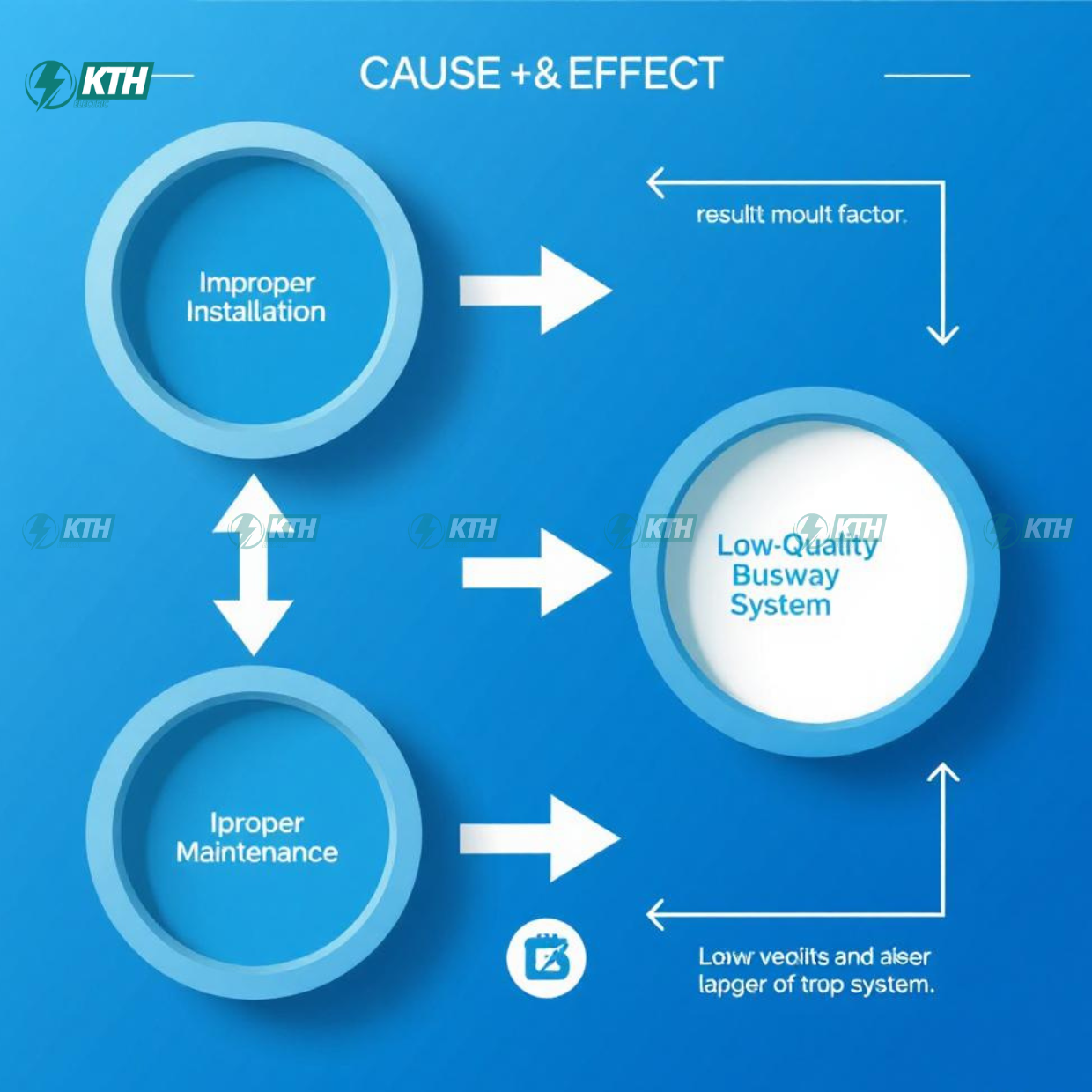

Analyzing Causes of Low-Quality Busway Systems

Maintenance Services Include:

- Detailed Inspection and Assessment:

- Determine operational duration and system length to plan appropriate maintenance.

- Conduct thermal scans of the entire Busway, especially at joints and Flugin boxes under load.

- In-Depth Analysis and Repairs:

- Analyze thermal scan results to develop a detailed maintenance plan.

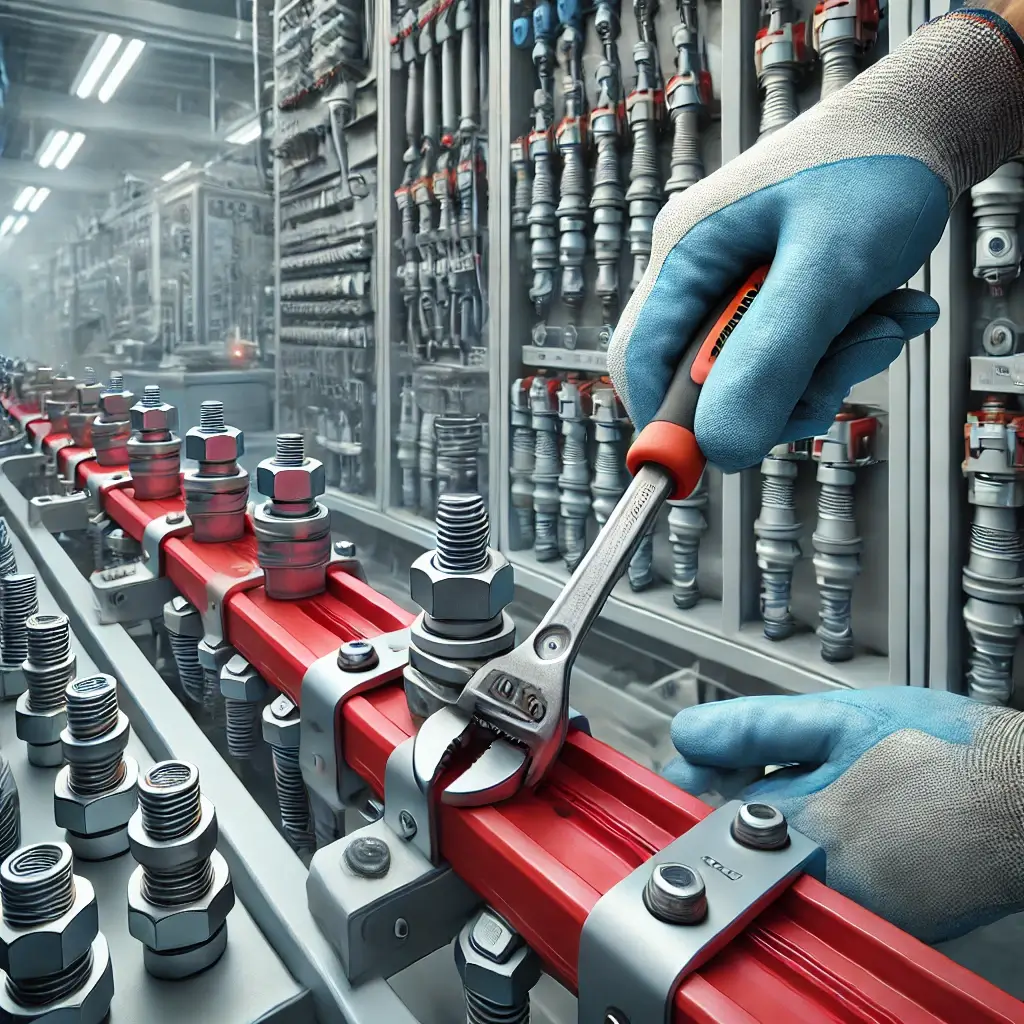

- Power down the system, tighten connections and Flugin boxes according to technical standards.

- Cleaning and Periodic Maintenance:

- Clean busbars, joints, and Flugin boxes using specialized equipment.

- Power up the system, recheck with thermal scans, and compare results before and after maintenance.

- Detailed Reporting:

- Provide maintenance reports with specific recommendations for improvement.

Benefits of Choosing KTH ELECTRIC:

- Enhances the safety and lifespan of the Busway system.

- Early detection and quick resolution of potential faults.

- Ensures stable and efficient system operation.

Don’t let faults disrupt your operations! Contact KTH ELECTRIC today for professional maintenance solutions.

What is Busway Maintenance?

Busway maintenance involves inspecting, cleaning, and repairing busway systems to ensure stable, safe, and efficient operations. Busways are widely used in high-rise buildings, factories, and industrial facilities due to their effective power distribution and flexible expandability.

Why is Busway Maintenance Needed?

Failure to perform periodic maintenance can lead to:

- Fire hazards: Increased temperature at connection points.

- Energy loss: Reduced transmission efficiency.

- Operational interruptions: Sudden busway system failures due to technical issues.

- Higher repair costs: Severe faults often require expensive repairs.

Benefits of Regular Busway Maintenance

- Ensures safety: Reduces risks of malfunctions and electrical accidents.

- Extends system lifespan: Minimizes wear and tear and prevents damage.

- Optimizes performance: Ensures stable power transmission through the busway.

- Saves costs: Early detection and resolution of minor issues prevent major expenses.

Standard Busway Maintenance Process

| Step | Description |

|---|---|

| 1. Initial Assessment | Inspect the overall condition, identify hotspots, and pinpoint areas requiring attention. |

| 2. Cleaning | Remove dust and debris from surfaces and joints to improve conductivity. |

| 3. Technical Inspection | Measure insulation resistance, check connections, and perform thermal scans at contact points. |

| 4. Repairs and Replacement | Resolve technical issues and replace faulty components, such as loose connections or worn busbars. |

| 5. Detailed Reporting | Prepare reports, analyze data, and provide maintenance recommendations. |

Essential Equipment for Busway Maintenance

| Equipment | Function |

|---|---|

| Insulation Tester (Megaohm) | Measures insulation resistance of the system. |

| Thermal Scanner | Detects hotspots and areas prone to overheating. |

| Power Meter (PM2230) | Measures power consumption and energy use. |

| Torque Wrenches | Ensures secure connections between joints. |

| Industrial Vacuum Cleaner | Clears dust and moisture from critical areas. |

Common Issues in Busway Systems

- Loose connections: Causes overheating and reduces efficiency.

- Electrical leakage: Poses safety hazards and lowers system reliability.

- Overheating at contact points: A common cause of fires.

- Insulation degradation: Affects electrical transmission performance.

Solutions to Enhance Maintenance Efficiency

- Utilizing IoT and Maintenance Management Software:

- Enables effective remote monitoring.

- Automatically alerts users to abnormalities.

- Training Technical Staff:

- Improves troubleshooting and problem resolution skills.

- Ensures adherence to proper procedures.

- Employing Modern Equipment:

- Increases accuracy in measurements and inspections.

Introducing KTH ELECTRIC Solutions

KTH ELECTRIC provides comprehensive busway maintenance services with outstanding advantages:

- Highly skilled technicians with professional training.

- Utilizes the latest technology for effective and safe operations.

- Fast maintenance services tailored to customer needs.

Conclusion

Busway maintenance not only ensures safety but also optimizes performance and reduces costs. Contact KTH ELECTRIC today for professional busway maintenance solutions.

📞 Hotline: 0968.27.1199

🌐 Website: KTH ELECTRIC

Tiếng Việt

Tiếng Việt