Overload relays are critical protective devices in any industrial electrical system, playing a key role in protecting motors from current-related faults. Their primary function is to detect current exceeding the allowable threshold and automatically open the circuit, preventing overheating and serious damage to the motor.

In this in-depth article, we will analyze the trip curve — the core factor that determines when and how an overload relay reacts. Understanding the characteristics of the trip curve not only enhances system reliability but also effectively protects equipment and extends motor lifespan.

Overview of the Trip Curve

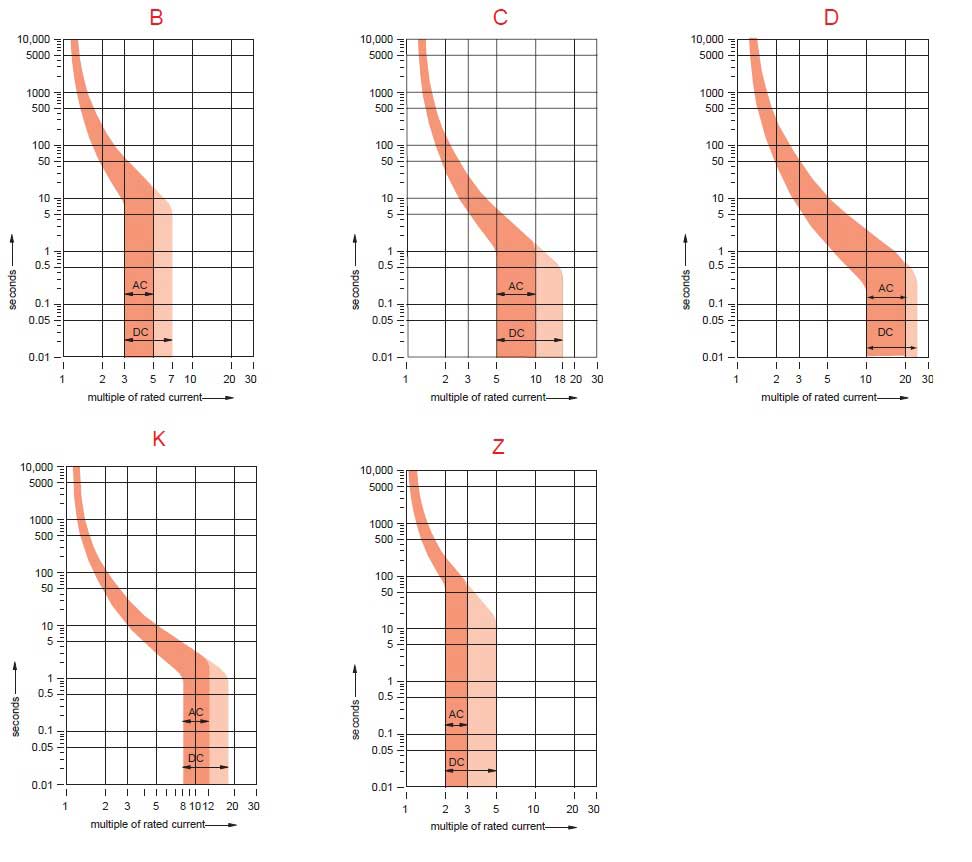

What is a Trip Curve? A trip curve is a graph that represents the relationship between the current intensity (as a multiple of the set current) and the time (in seconds) that the relay requires to activate (trip the circuit).

Trip Curve (time-current characteristic curve) is a graph showing the relationship between current intensity and the tripping time of an overload relay.

This is the most critical graph that helps engineers determine the relay’s response capability when the current exceeds the set threshold.

- Horizontal axis (X): Represents the current intensity as a multiple of the set value (e.g., 1.2x, 6x).

- Vertical axis (Y): Represents the trip time in seconds.

How to read it: To read the curve, find the current multiple on the X-axis (e.g., 6x the set current), draw a vertical line up until it intersects the curve, then draw a horizontal line to the Y-axis to determine the trip time.

In most applications, the trip curve uses a logarithmic scale, making it easy to observe and compare values over a wide current range. This curve must be selected to match the motor’s thermal characteristics, ensuring the relay trips before the motor is damaged by overheating.

Practical Application:

- Measure the motor’s Full Load Amps (FLA).

- Set the relay between 100-125% of FLA (depending on standards and motor type).

- Check the curve at 600% FLA (corresponding to starting current) to select the appropriate Trip Class.

Trip Class for Overload Relays Explained

What is a Trip Class? A Trip Class is a standard parameter that defines the maximum time (in seconds) a relay will take to trip when subjected to a current 6 times (600%) its rated current. For example: Class 10 = 10 seconds.

Trip Class is a standard parameter (per IEC 60947-4-1) that defines the maximum time (in seconds) for an overload relay to trip when the motor experiences a current of 6 times its rated current (600% FLA).

This is the most important parameter for classifying relays, helping to select the appropriate protective device for the starting requirements of each load type.

Common Trip Classes (Data per IEC standard):

| Trip Class | Trip time at 600% rated current | Suitable Application |

|---|---|---|

| Class 10 | 10 seconds (or less) | Fast start (under 10s), hermetic compressors, submersible pumps. |

| Class 20 | 20 seconds (or less) | Medium load, general-purpose applications. |

| Class 30 | 30 seconds (or less) | Heavy loads, high inertia, requiring long start times (large industrial fans, crushers). |

Selection Strategy:

- Fast-start applications (e.g., pumps): Prioritize Class 10 to ensure an immediate response in case of a locked rotor.

- Heavy-load, slow-start applications (e.g., fans, heavy conveyors): Use Class 20 or Class 30 to avoid nuisance trips during the normal startup process.

Selecting the wrong Trip Class can lead to two scenarios:

- Selecting a Class that is too low (e.g., Class 10 for a heavy load): Causes “nuisance trips,” leading to continuous machine stoppage during startup, affecting production.

- Selecting a Class that is too high (e.g., Class 30 for a light load): The relay will not trip fast enough during a fault, leading to motor overheating and burnout.

Characteristics and Differences: Cold State vs. Hot State

What is the difference between ‘cold’ and ‘hot’ trip curves? A relay in a ‘cold state’ (starting from ambient temperature) will trip slower. A relay in a ‘hot state’ (already warmed up from operation) will trip significantly faster (often 20-30%) because it is already near its thermal trip threshold.

Overload relays (especially thermal relays) exhibit different trip curves depending on their initial temperature.

- Cold State Trip Curve: Applies when the relay starts from ambient temperature (e.g., below 40°C). In this state, the relay requires more time to accumulate enough heat to trip (often 20-30% slower).

- Hot State Trip Curve: Applies when the relay has been operating and has warmed up due to the load current. In this state, the relay is already “near the threshold” and will react significantly faster to an overload.

Why is this important? In applications with frequent start/stop cycles, the motor will always operate in a hot state. Design engineers must account for both states. Modern relays often feature “thermal memory” to simulate the hot state, ensuring accurate protection even when restarting after a fault.

To ensure safety, periodic thermal scanning of electrical cabinets also helps detect abnormal hot spots at the relay, a sign of a loose connection or a relay operating near its threshold.

Two-Phase vs. Three-Phase Trip Curves

How does a relay react to a phase loss? When a phase is lost, the relay will detect the imbalance and trip faster than its standard curve (typically at 105-120% of the set current), even if the current in the remaining two phases is not in an overload condition, to protect the motor.

Trip curve characteristics also differ when the relay operates in a balanced three-phase system versus when a fault (like phase loss) occurs.

- Three-phase (Balanced): When the load is balanced, all three bimetallic elements in the thermal relay heat evenly. The trip time will follow the standard curve (e.g., Class 10).

- Two-phase (Unbalanced): When a single-phasing fault occurs, current only flows through the two remaining phases. This causes a severe imbalance. Modern overload relays are designed to detect this imbalance. They will trip faster than the standard curve (often tripping at 105-120% of the set current), even if the current in the remaining two phases has not reached an overload level.

This feature is extremely important because running a three-phase motor in a phase-loss condition will cause rapid overheating and motor burnout. Some systems use an additional dedicated phase protection relay to enhance this layer of protection.

Conclusion: The Importance of Choosing the Right Relay

Understanding the trip curve is a key factor in effective motor protection. Selecting the correct Trip Class, understanding the difference between hot/cold states, and the capability for phase-loss protection are mandatory for ensuring operational safety.

At CHINT, we provide a reliable protection solution with the NXR Thermal Overload Relay, meeting strict international standards:

- Comprehensive protection: Effective overload and phase-failure protection (trip characteristic per Class 10).

- Wide operating range: 50/60 Hz frequency, voltage up to 690 V, current from 0.1 – 630 A.

- Reliable: Integrated ambient temperature compensation and a clear trip status indicator.

- Flexible: Can be mounted directly onto a contactor or installed independently.

CHINT’s solution is designed to optimize protection capabilities, ensure operational continuity, and minimize the risk of equipment damage.

Important Notes on Storage and Operation

-

- Check Settings: Always set the relay current according to the motor’s FLA. Setting it too high will cause the motor to overheat; setting it too low will cause nuisance trips.

- Periodic Testing: Use the “Test” button on the relay and check the contacts with a multimeter. (Should be combined with regular electrical system maintenance services).

s

- Avoid High Ambient Temperatures: Thermal relays are sensitive to temperature. The trip time will decrease at >40°C and increase at <40°C (except for temperature-compensated types).

- Troubleshooting: If the relay trips frequently, check the mechanical load, use a clamp meter to measure the 3-phase current, and check the motor’s insulation resistance.

Frequently Asked Questions (FAQ)

Which trip class is most common? Class 10 is the most common for standard motors needing fast protection. Class 20 is used for loads with slightly longer startup times.

How to reset the relay after a trip? Most relays have a “Reset” button. You can select Manual (must press the button) or Auto (resets automatically after cooling). Recommendation: Always use Manual Reset and investigate the cause of the trip before restarting.

Do overload relays protect against short circuits? No. Overload relays (thermal) only protect against prolonged high currents (overload). You must use a fuse or a Circuit Breaker (CB/MCB/MCCB) for short-circuit protection.

Does the CHINT NXR relay support phase loss detection? Yes. The NXR relay has a phase failure detection mechanism and will trip faster to protect the motor.