TECHNICAL GUIDE: RECLOSER CLASSIFICATION BY INTERRUPTING MEDIUM & CONTROLS (2025)

1. Classification by Interrupting Medium

Understanding the interrupting medium is essential as it dictates the Operations & Maintenance (O&M) schedule and the equipment’s lifecycle. The shift from oil to vacuum technology represents the most significant evolution in medium-voltage distribution equipment.

A. Oil Interrupters

This is the traditional technology where oil serves a dual critical role:

- Function: It is used to quench the electric arc generated during circuit interruption AND acts as the basic insulation medium.

- Mechanism: Some reclosers with hydraulic controls utilize the pressure of this same oil for timing and counting functions.

- Operational Drawback: Oil degrades over time and with the frequency of interruptions. This necessitates regular oil sampling, filtration, or replacement, resulting in higher O&M costs and potential environmental hazards from leakage.

B. Vacuum Interrupters

This is the modern industry standard for medium-voltage distribution.

- Speed: Provides fast, low-energy arc interruption (typically within 1-3 cycles).

- Longevity: Contact and interrupter life far exceeds that of oil media, often lasting the life of the pole mechanism.

- Safety: Minimizes fire risks associated with oil pressure buildup.

- Mechanical: Reduces mechanical stress on moving parts due to shorter travel distances.

Insulation Note: While the arc is quenched in a vacuum bottle, the external insulation medium (ensuring phase-to-phase and phase-to-ground isolation) can vary:

- Oil

- Air

- Epoxy (Solid Dielectric) – Current trend for maintenance-free operation.

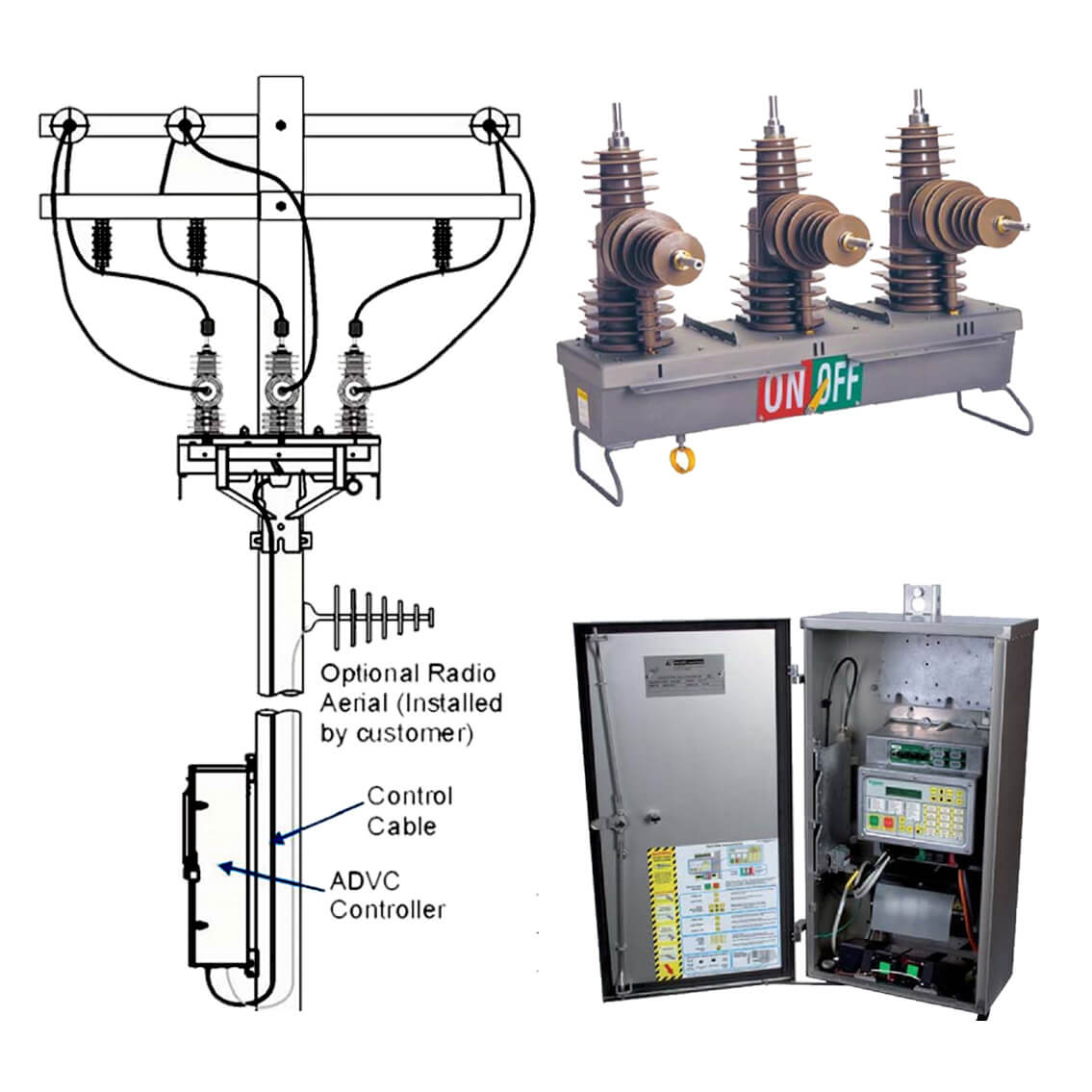

2. Control Systems

The control unit is the “brain” of the recloser, determining grid reliability.

Electronic Controls

Electronic controls have been widely deployed since the mid-1980s (e.g., the Eaton Form 7 series) and remain prevalent in many grids today.

Technical Features:

- Offer programmable protection settings (overcurrent, earth fault, sensitive earth fault).

- Event logging capabilities to assist in post-fault analysis.

- Integration with SCADA for Smart Grid automation and remote switching.

Current Status: While many electronic controls from the 80s and 90s are still operational, the industry is shifting toward microprocessor-based relays for advanced diagnostics, though the fundamental electronic logic remains valid.

3. Quick Technical Comparison Table

| Feature | Oil Interrupters | Vacuum Interrupters |

|---|---|---|

| Arc Quenching Principle | Uses oil energy/pressure | Uses vacuum environment |

| Maintenance | High (Oil changes, filtration) | Low (Interrupter is sealed) |

| Contact Life | Moderate | Very High |

| Safety Risks | Fire risk (if oil degrades/leaks) | Minimal risk |

| Typical Application | Legacy grids, rural areas | Modern grids, urban areas, Substations |

4. Operational Recommendations (Actionable Steps)

If you manage a grid containing both technologies, implement the following:

- For Oil Reclosers: Establish a strict maintenance schedule (every 6-12 months) to test dielectric breakdown voltage and oil levels.

- For Vacuum Reclosers: Focus inspection on the mechanical linkage and the external insulation (bushings/tank), as the vacuum bottle itself rarely fails.

- Upgrade Strategy: If you are using legacy hydraulic controls, consider a Control Retrofit. You can upgrade to an electronic control (like the Form 7 or newer) to gain remote monitoring capabilities without replacing the entire recloser tank.