The Ultimate Guide to 100 Amp Breakers: Wire Size, Capacity, and Installation (NEC Standards)

The Role of a 100 Amp Breaker in Modern Electrical Systems

In the anatomy of a building’s electrical system, the main circuit breaker acts as the heart—regulating the flow of energy and, more importantly, stopping that flow before a catastrophe occurs. Specifically, the 100 amp breaker serves as the standard gatekeeper for millions of older homes, detached garages, subpanels, and small industrial workshops.

As an electrical engineer with over two decades of field experience, I have inspected thousands of electrical panels, ranging from the humid environments of Ho Chi Minh City to the fluctuating climates of North Carolina. I have seen the devastating aftermath of improper sizing—melted insulation, charred busbars, and electrical fires that could have been prevented with basic knowledge of the National Electrical Code (NEC).

The 100 amp breaker is not just a switch; it is a precisely calibrated thermal-magnetic device designed to protect your wiring from overheating. Whether you are looking to upgrade your service panel, install a subpanel for a new workshop, or simply replace a failing unit, understanding the physics and code requirements behind this device is non-negotiable.

Brought to you by KTH Electric Co., Ltd. – Your trusted partner in electrical infrastructure.

VN Address: 251 Pham Văn Chiêu, An Hội Tây Ward, Ho Chi Minh City | Hotline: 0968.27.11.99

US Address: 2936 Pear Orchard Rd, Yadkinville, NC 27055 | Hotline: 1 (336) 341-0068

Email: kthelectric.com@gmail.com

Critical Wire Size Requirements for 100 Amp Breakers

Quick Answer

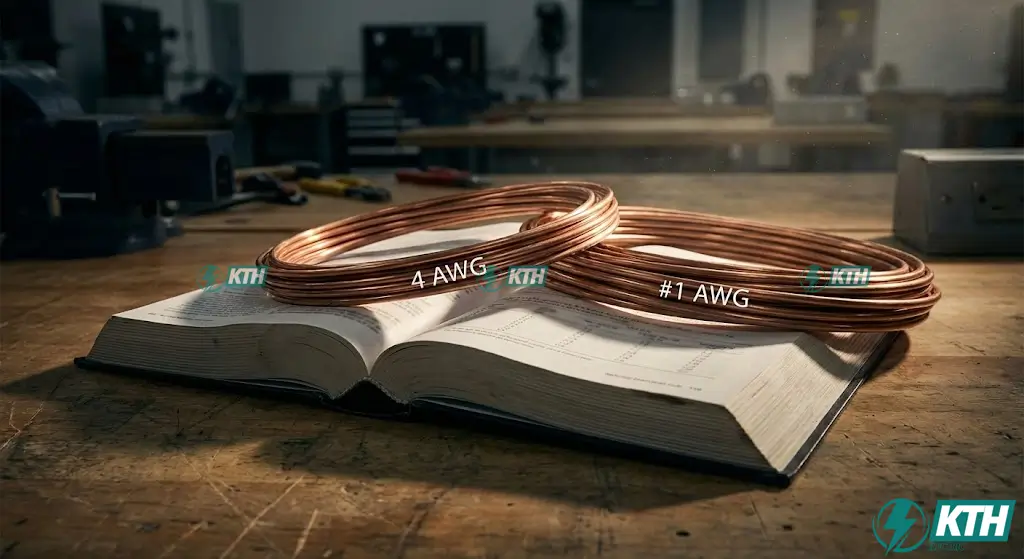

The required wire size depends on the circuit type (Service vs. Feeder) and material. For general load circuits (NEC 310.16), use **#1 AWG Copper** or **1/0 AWG Aluminum**.

The Core Rule: NEC Table 310.16 vs 310.12(A)

To answer this accurately, we must refer to the “Bible” of the industry: the **NEC (National Electrical Code)**. There are two distinct tables you must know:

1. NEC Table 310.16 (General Wiring)

Applies to dedicated circuits, feeders to subpanels, and non-residential applications.

2. NEC Table 310.12(A) (Residential Service)

Applies only to the main service entrance conductors powering an entire dwelling unit (single-phase).

Copper Wire Sizing Breakdown

Copper is the gold standard for conductivity. It carries current more efficiently than aluminum and is more resistant to heat expansion.

- #4 AWG Copper: Rated for 85 Amps at 75°C. Only allowed for 100A Main Residential Service. For any other 100A circuit, it is undersized.

- #3 AWG Copper: Rated for 100 Amps at 75°C. This is the minimum code-compliant size for THHN/THWN feeders in conduit.

- #2 AWG Copper: Rated for 115 Amps at 75°C. At KTH Electric, we recommend this for subpanels. The extra thickness reduces voltage drop.

- #1 AWG Copper: Rated for 130 Amps at 75°C. The absolute safest bet for long runs or continuous loads.

Aluminum Wire Sizing Breakdown

Aluminum is lighter and significantly cheaper, making it the preferred choice for long feeders. However, it is less conductive.

- #2 AWG Aluminum: Rated for 90 Amps at 75°C. Allowed only for 100A Main Residential Service. For subpanels/feeders, this is undersized.

- #1 AWG Aluminum: Rated for 100 Amps at 75°C. Minimum requirement for standard feeders.

- 1/0 (One-Ought) Aluminum: Rated for 120 Amps at 75°C. Industry standard for subpanels. Widely available in SER cables.

Grounding Electrode Conductor Sizing

For a 100 Amp service using #2 Copper or 1/0 Aluminum service conductors, NEC Table 250.66 requires:

- #8 AWG Copper grounding electrode conductor (minimum).

- #6 AWG Aluminum grounding electrode conductor (minimum).

Most electricians will use #6 AWG solid copper for the grounding rod connection to ensure mechanical durability.

Suitable Cable Types for a 100A Breaker

Selecting the right wire gauge is only half the battle; the insulation type must match the environment.

THHN/THWN-2

Individual wires in conduit. Excellent for commercial wet/dry locations.

SER Cable (Service Entrance Reinforced)

Round, jacketed cable usually containing Aluminum conductors (e.g., 1-1-1-3). Ideal for indoor runs to feed subpanels.

SE-U / SE-R

Used for connecting the utility transformer to the main meter and panel. SE-R has a ground wire; SE-U does not.

XHHW-2

Cross-linked polyethylene insulation. More durable and moisture-resistant than THHN. Great for underground conduits.

UF-B (Underground Feeder)

Designed for direct burial without conduit. Typically copper and rarely seen in sizes large enough for 100A due to cost and stiffness.

MC (Metal Clad)

Armored cable for industrial environments where physical protection is needed.

100 Amp Service Capacity: What Can It Power?

Quick Summary

A 100A panel is generally sufficient for gas-heated homes under 2,500 sq ft. For continuous loads (like EV charging), you are limited to 80 Amps (80% rule) to prevent overheating.

Many older homes in the US and standard apartments in Vietnam operate on 100 amp service. The question is, in an era of induction cooktops and EV chargers, is it enough?

The 80% Safety Rule (Continuous Loads)

In electrical engineering, we classify loads into two categories: continuous (running 3 hours or more) and non-continuous. For continuous loads—like electric vehicle chargers, lighting systems, or heaters—you should not exceed 80% of the breaker’s capacity.

Equation

$100 \text{ Amps} \times 0.80 = 80 \text{ Amps}$

Pushing a breaker to 100% capacity for hours will cause nuisance tripping and thermal degradation.

Calculating Wattage Capacity (Watts = Volts × Amps)

120V Circuit

- Max: 12,000 Watts

- Safe Continuous (80%): 9,600 Watts

240V Circuit (Standard Service)

- Max: 24,000 Watts (24 kVA)

- Safe Continuous (80%): 19,200 Watts (19.2 kVA)

Demand Factors & Upgrades

NEC Tables 220.42 and 220.45 allow for “Demand Factors.” This means code recognizes that you don’t run every appliance simultaneously.

When to Upgrade to 200 Amps?

- Stick with 100A if: Gas appliances, home < 2,500 sq ft, no EV.

- Upgrade to 200A if: Fully electric home, Heat pump, Level 2 EV Charger (48A+), or large additions.

Types of 100 Amp Circuit Breakers

Not all breakers are created equal. Identifying the correct physical form factor is critical for installation.

WARNING: Brand Compatibility

Never mix brands unless “Classified”. Square D QO vs Homeline are NOT interchangeable. Eaton CH vs BR are NOT interchangeable. Wrong brands void UL listing and insurance.

Installation Guide: Feeding a 100 Amp Subpanel

Installing a 100 amp subpanel is one of the most common upgrades we perform. It requires strict adherence to wiring protocols.

1. Feeder Wire Selection

- SER Cable: 1-1-1-3 Aluminum SER is the standard choice for running through interior framing.

- Conduit Run: Three #3 Copper or #1 Aluminum wires (Hot, Hot, Neutral) plus a #8 Copper or #6 Aluminum Ground.

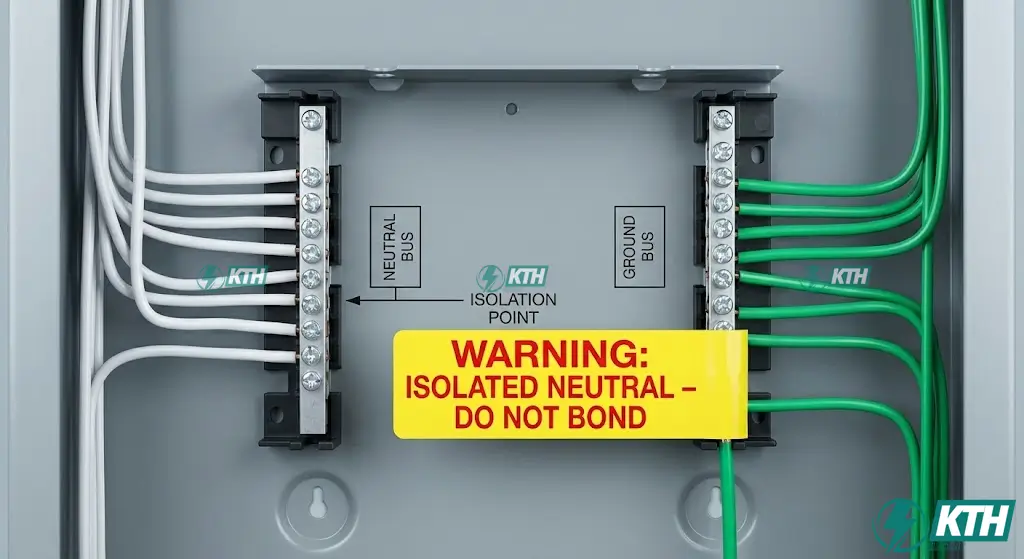

2. Separating Neutrals and Grounds: The Critical Rule

Main Panel: Neutrals and Grounds are bonded together. Subpanel: They MUST be isolated.

- Install separate ground bar kit.

- Remove green bonding screw connecting the neutral bar to the metal case.

- Why? Bonding them at the subpanel creates parallel paths for return current on the metal casing, creating a serious shock hazard.

3. Torque Specifications: The “Hand-Tight” Myth

“Hand-tight” is dangerous. NEC 110.14(D) requires torquing to manufacturer specs. For 100A lugs, use a torque wrench to reach 45-50 inch-pounds. Do not guess.

Troubleshooting Common 100 Amp Breaker Issues

1. Tripping Under Load

Symptom: Trips when Dryer + AC + Oven run.

Diagnosis: Overload. Measure total amps with a clamp meter. If it exceeds 100A (or 80A continuous), you need a service upgrade.

2. Tripping Instantly (No Load)

Symptom: Trips immediately on reset.

Diagnosis: Short Circuit / Dead Short. A hot wire is touching ground/neutral in the feeder or panel. Do not force reset!

3. Heat or Buzzing

Symptom: Hot to touch / sizzling sound.

Diagnosis: Arcing. Loose connection. If hot, internal contacts are carbonized. **Replace immediately.**

Cost Analysis (Vietnam vs. US Market)

| Region | Component Cost | Labor Estimate |

|---|---|---|

| United States (NC) | Breaker: $60-$120 USD. Wire (#2 Cu): ~$4-6/ft. |

$1,500 – $3,000+ |

| Vietnam (HCMC) | MCCB (100A): 800,000 – 2,500,000 VND ($32-$100 USD). | Varies (Strict TCVN compliance required) |

Frequently Asked Questions

Q: Can I use 2 gauge (2 AWG) wire for a 100 amp service?

A: Yes, if it is Copper. #2 Copper is rated 115A at 75°C. For Aluminum, you must use 1/0 AWG (except for main residential service where #2 Aluminum is permitted by specific code tables).

Q: Is 100 amp service enough for a modern house?

A: Yes for gas homes <2,500 sq ft. No for all-electric homes with EV chargers and tankless water heaters.

Q: Can I replace a 100 amp main breaker myself?

A: Strongly advised against. The “Line Side” lugs are always live even when the breaker is off. Pulling the meter is dangerous and often illegal for non-professionals. Risk of arc flash is high.

Conclusion

The 100 amp breaker is a robust, essential component of modern electrical infrastructure. Whether coping with the heat of Vietnam or the power demands of the US, the physics remain the same: Respect the load limits, size the wire correctly (#1 Cu / 1/0 Al for general use), and torque your connections.

Improper sizing or loose connections are not just code violations; they are fire hazards.

Contact Us for a Consultation:

Vietnam: 251 Pham Van Chieu, An Hoi Tay Ward, Ho Chi Minh City | Hotline: 0968.27.11.99

USA: 2936 Pear Orchard Rd, Yadkinville, NC 27055 | Hotline: 1 (336) 341-0068

Email: kthelectric.com@gmail.com