Knowledge

Circuit Breaker vs. Isolating Switch: Key Differences & Safety Guide

Circuit Breaker vs. Isolating Switch: Key Differences & Safety Guide (2025)

Quick Answer:

A Circuit Breaker is an automatic protective device designed to interrupt current flow when faults (overload or short circuits) are detected; it contains an arc-extinguishing chamber to handle live loads safely. Conversely, an Isolating Switch (or Disconnector) is a manual device used to create a “visible break” in the circuit for maintenance safety. Ideally, an isolator should never be operated while current is flowing unless specifically rated as a Load Break Switch.

1. The Circuit Breaker: The Automated “Bodyguard” of Electrical Systems

Quick Insight: A Circuit Breaker acts as a resettable automatic switch that protects electrical circuits from damage caused by excess current from overloads or short circuits.

The Circuit Breaker acts as the primary defense mechanism against catastrophic electrical failures. Unlike a fuse, which operates once and must be replaced, a circuit breaker is a mechanical switching device capable of being reset and reused after clearing a fault.

For comprehensive facility management, understanding these devices is the first step in a proper electrical system assessment.

Core Functions and Protection Mechanisms

Quick Insight: Circuit breakers provide two main layers of defense: thermal protection for prolonged overcurrents and magnetic protection for instant short-circuit surges.

A circuit breaker is a sophisticated sensing device designed to protect conductors and equipment from two primary threats:

- Overload Protection (Thermal):

The Scenario: This occurs when the current draw exceeds the rated capacity of the circuit for an extended period.

The Mechanism: A bi-metal strip inside the breaker heats up and bends. This relates closely to the principles found in overload relays and trip curves, where specific time-current characteristics determine when the device cuts power. - Short Circuit Protection (Magnetic):

The Scenario: A “hard” fault where a hot wire contacts a neutral or ground wire, causing amperage to spike to thousands of amps in milliseconds.

The Mechanism: An electromagnet (solenoid) inside the breaker detects this massive surge instantly and forces the contacts apart to prevent an explosion.

Types of Circuit Breakers by Application

Quick Insight: Selection depends on voltage and load: MCBs for residential/commercial use, MCCBs for heavy industry, and Reclosers for outdoor utility lines.

To comply with safety standards like IEC 60898 and IEC 60947-2, engineers select specific breakers for specific roles:

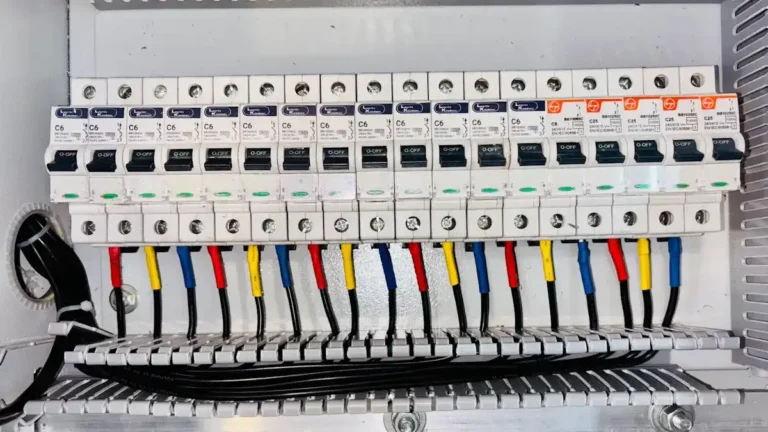

- MCB (Miniature Circuit Breaker): The standard breaker found in residential and commercial low voltage electrical cabinets. It typically mounts on a DIN rail and handles currents up to 100A.

- MCCB (Molded Case Circuit Breaker): A robust, industrial-grade device used in commercial distribution. It can handle massive loads (up to 2500A).

- Recloser: In medium-voltage outdoor distribution, a recloser is a specialized type of circuit breaker that can automatically test the line and “re-close” if the fault was temporary, unlike a standard breaker that stays open.

2. The Isolating Switch: The “Visible Break” for Maintenance Safety

Quick Insight: An Isolating Switch is a manual safety device used to physically disconnect a circuit, creating a visible gap to ensure absolute safety for maintenance personnel.

While the circuit breaker protects the wiring, the Isolating Switch (or Disconnector) protects the technician. In industrial settings and transformer stations, relying solely on a breaker’s “off” position is insufficient for life-safety assurance.

Core Functions and The “Visible Gap”

Quick Insight: Isolators ensure total physical segregation from power sources and enable Lockout/Tagout (LOTO) protocols to prevent accidental reactivation.

The defining characteristic of an isolating switch is its ability to provide a visible break distance. When the handle is in the “OFF” position, there is a physical, observable gap between the contacts, ensuring that voltage cannot jump across to the equipment being serviced.

- Total Isolation: It physically segregates a section of the electrical network from the power source.

- Lockout/Tagout (LOTO) Compliance: Isolators are designed with padlocking facilities. This allows a maintenance engineer to lock the switch in the “OPEN” position, ensuring nobody can accidentally re-energize the system while work is in progress.

The Cardinal Rule: “No-Load Operation”

Quick Insight: NEVER open a standard isolator under load. Always trip the circuit breaker first to stop current flow before operating the isolator.

This is the most critical safety distinction.

- The Danger: Most standard isolating switches lack arc quenching chambers.

- The Consequence: If you open an isolating switch while high current is flowing (under load), a massive electric arc will form.

- The Protocol: You must always open the circuit breaker first. Only then is it safe to open the isolating switch.

3. Detailed Engineering Comparison: Circuit Breaker vs. Isolating Switch

Quick Insight: Breakers handle faults automatically and can switch under load. Isolators are manual, cannot switch under load, and are placed upstream for safety isolation.

To select the correct device for your distribution panel, you must understand the technical nuances outlined below.

| Feature / Attribute | Circuit Breaker (MCB/MCCB) | Isolating Switch (Disconnector) |

|---|---|---|

| Primary Function | Automatic Protection: Shields the system from overloads and short circuits. | Manual Isolation: Creates a safe, dead circuit for maintenance. |

| Operation Mode | Automatic (trips on fault) & Manual. | Manual Only (100% human operated). |

| Arc Quenching | High Capability: Contains arc chutes to suppress sparks during load breaking. | None/Low: Cannot suppress arcs; contacts will burn if opened under load. |

| On-Load Operation | Permitted: Designed to switch live loads ON and OFF. | Prohibited: Must only be operated when current is zero (unless rated as a Load Break Switch). |

| Position in Circuit | Downstream (closer to the load/equipment). | Upstream (closer to the source) or both ends for total isolation. |

4. System Integration: The Critical Operational Sequence

Quick Insight: For safety, strict sequencing is mandatory: Shutdown = Breaker OFF then Isolator OFF. Startup = Isolator ON then Breaker ON.

In high-voltage substations, industrial factories, and complex commercial systems, these two entities function as a pair. This coordination is a key part of electrical system maintenance services.

The Safe Shutdown Sequence (De-energizing):

- Open the Circuit Breaker: This cuts the load current safely.

- Verify Status: Confirm the breaker has tripped.

- Open the Isolating Switch: Now that there is no load, open the isolator to create the physical air gap.

- LOTO Procedure: Apply locks and tags.

- Verify Isolation: Use a voltage tester to confirm the equipment is “dead.”

5. Maintenance, Testing, and Environmental Considerations

Quick Insight: Robust maintenance involves regular functional tests for breakers and mechanical checks for isolators to comply with IEC and local standards.

To comply with regulations such as BS 7671:2018 and international IEC standards, a robust maintenance schedule is required. Neglecting these devices can lead to “stuck” mechanisms or failure to trip during a fault.

Routine Testing Protocols

Quick Insight: Utilize thermal imaging to detect loose connections early and partial discharge testing for high-voltage equipment integrity.

- Functional Testing:

– GFCI/RCCB: Press the “TEST” button monthly.

– Reclosers: Specialized recloser maintenance services are required for outdoor distribution equipment to ensure auto-reclosing logic is functioning. - Advanced Diagnostic Scanning:

– Thermal Imaging: Loose connections in breakers generate heat before they fail. A professional thermal scan electrical cabinet service can detect these hotspots non-invasively.

– Partial Discharge: For high-voltage isolators and breakers, silent degradation can be detected early via online partial discharge measurement services.

Indicators of Failure: When to Replace

Quick Insight: Immediate replacement is needed if you see contact charring, physical casing cracks, or experience nuisance tripping.

- Nuisance Tripping: If a breaker trips instantly after reset with no load attached, the internal spring mechanism or sensing coil has failed.

- Contact Charring: Black marks on an isolating switch indicate it was operated under load or has a loose connection.

- Physical Damage: Any crack in the casing compromises the dielectric strength. In critical infrastructure like substations, this often requires immediate medium voltage cabinet maintenance services.

Frequently Asked Questions (FAQ)

Next Step for Facility Managers:

Don’t wait for a failure. Ensure your transformer maintenance and switchgear protocols are up to date. Check your main distribution panel today and ensure all LOTO procedures are clearly documented.

For expert assistance with your electrical infrastructure, Contact KTH Electric or learn more About Us.

With over 12 years of hands-on experience in the industrial electrical sector, I specialize in delivering optimized technical solutions for factories and industrial zones.

My core expertise includes: Power System Design, Substation Installation, and Heavy-Duty System Maintenance.

Tiếng Việt

Tiếng Việt