Electrical System Maintenance Service

Industrial Electrical System Maintenance: Comprehensive and Reliable Service at KTH ELECTRIC

Industrial electrical systems play an essential role in every production process. A stable electrical system not only ensures operational efficiency but also minimizes unforeseen risks. However, without proper and regular maintenance, electrical equipment can fail, leading to significant losses. Let’s explore the importance of electrical system maintenance, the process, and the benefits offered by KTH ELECTRIC.

What Is Electrical System Maintenance and Why Is It Important?

Electrical system maintenance involves inspecting, cleaning, repairing, and upgrading electrical equipment to ensure safe, efficient, and stable operations. This is a necessary task to prevent failures and extend the lifespan of the system.

The Importance of Electrical System Maintenance

- Ensure safety: Reduces the risk of fires and protects workers and assets.

- Maintain performance: Enhances the operational efficiency of equipment.

- Optimize costs: Prevents major failures and reduces emergency repair costs.

- Minimize downtime: Ensures uninterrupted production processes.

| Key Benefits | Description |

|---|---|

| Ensure workplace safety | Reduces risks of accidents and fires. |

| Enhance equipment efficiency | Ensures stable and efficient operations. |

| Minimize downtime | Guarantees continuous production. |

| Cost savings | Early detection of issues reduces major repair costs. |

Types of Electrical System Maintenance

1. Preventive Maintenance

Periodic inspections and replacement of components showing signs of wear before failures occur.

2. Corrective Maintenance

Repairs equipment after failures to restore functionality.

3. Predictive Maintenance

Uses modern technologies (like sensors, measurement tools) to analyze and predict potential failures.

4. Scheduled Maintenance

Conducted on a specific schedule to maintain system stability and efficiency.

| Maintenance Type | Description |

|---|---|

| Preventive Maintenance | Inspects and replaces components before failures occur. |

| Corrective Maintenance | Fixes issues when equipment has stopped working. |

| Predictive Maintenance | Uses analytics to forecast failures. |

| Scheduled Maintenance | Regular checks to maintain performance. |

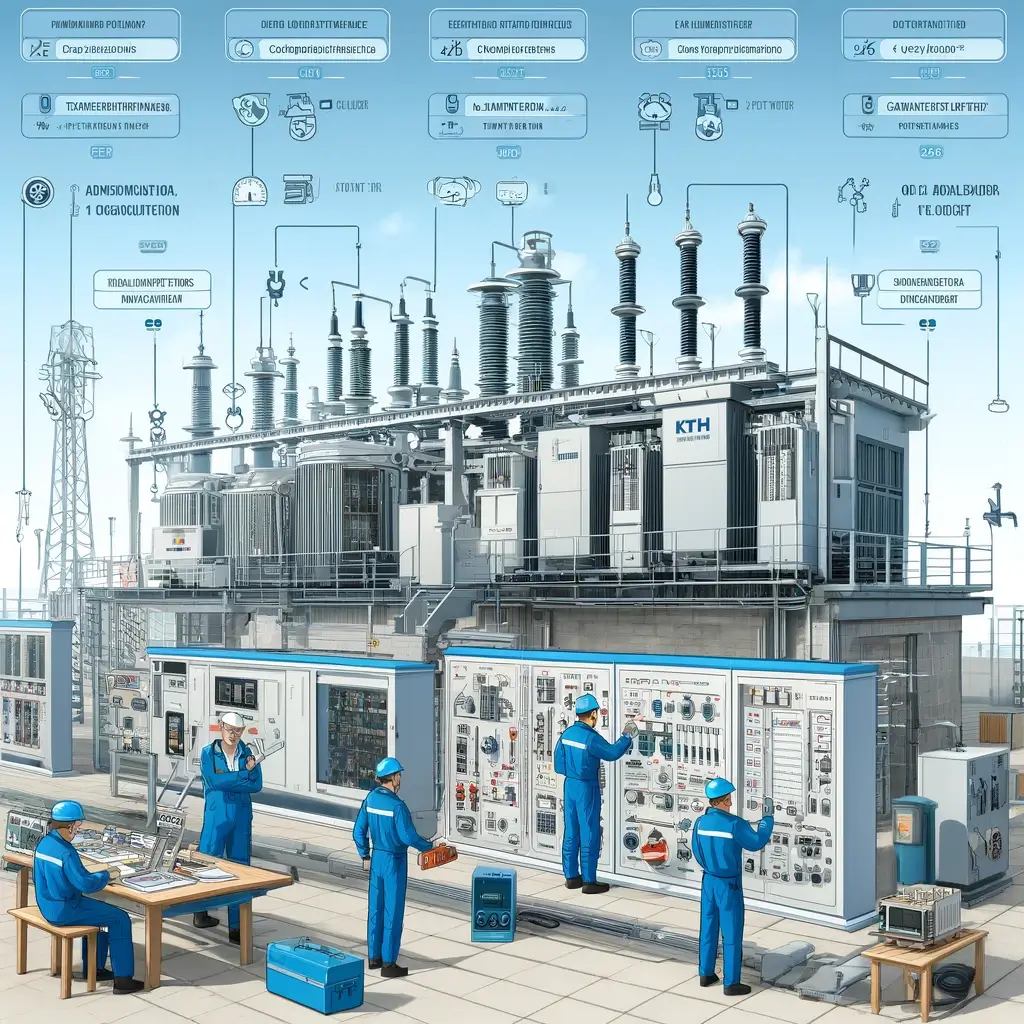

Maintenance Process at KTH ELECTRIC

KTH ELECTRIC offers maintenance services following international standards, ensuring professionalism and efficiency.

| Step | Task Description |

|---|---|

| Preparation and Evaluation | Inspect system conditions and assess equipment requiring maintenance. |

| Maintenance Execution | Clean equipment, replace old components, and verify technical specifications. |

| Post-Maintenance Inspection | Ensure the system operates stably and efficiently. |

| Reporting and Consultation | Provide detailed reports and recommendations for the next maintenance. |

Key Electrical Equipment for Maintenance

| Equipment | Maintenance Task |

|---|---|

| Transformers | Measure insulation, check oil, clean cores. |

| Industrial Electrical Panels | Inspect protective relays and circuit breakers. |

| Cables and Lines | Test insulation resistance and detect physical damages. |

| Sensors and Measuring Devices | Calibrate measurement devices and replace when needed. |

Key Standards and Specifications in Electrical Maintenance

| Specification | Standard Value |

|---|---|

| Rated Voltage | As required by the system. |

| Maximum Current | Per equipment design. |

| Operating Frequency | 50 Hz or 60 Hz. |

| Minimum Insulation Resistance | > 1 MΩ |

Maintenance Cost

| Maintenance Type | Estimated Cost |

|---|---|

| Scheduled Maintenance | From 5,000,000 VND |

| Large System Maintenance | From 20,000,000 VND |

Factors Affecting Cost:

- System scale.

- Equipment condition.

- Maintenance location.

- Maintenance type (preventive, scheduled, predictive, corrective).

Professional Maintenance Services at KTH ELECTRIC

Why Choose KTH ELECTRIC?

- Modern Technology: Uses the latest testing equipment.

- Professional Team: Experienced and well-trained technicians.

- Comprehensive Solutions: Includes inspection, monitoring, and repairs.

- Dedicated Support: Customer support available 24/7.

Frequently Asked Questions

| Question | Answer |

|---|---|

| How often should electrical systems be maintained? | At least once every six months for large industrial systems. |

| How do I know when maintenance is needed? | When there are unusual noises, high temperatures, or unstable equipment. |

| Does KTH ELECTRIC provide warranties? | Yes, KTH ELECTRIC offers warranties post-maintenance. |

Conclusion: Ensuring Efficiency with KTH ELECTRIC Maintenance Services

KTH ELECTRIC is a leading provider of professional electrical system maintenance services. Investing in regular maintenance ensures your electrical system operates stably, saves costs, and guarantees safety.

Learn more about our Thermal Scan Service.

📞 Hotline: 0968.27.1199

📧 Email: info@kth-electric.com

🌐 Website: kth-electric.com

KTH ELECTRIC – Comprehensive and reliable solutions for your electrical maintenance needs!

Tiếng Việt

Tiếng Việt