William

Senior Industrial Electrical Specialist | KTH ELECTRIC

With over 12 years of hands-on experience in the industrial electrical sector, I specialize in delivering optimized technical solutions for factories and industrial zones.

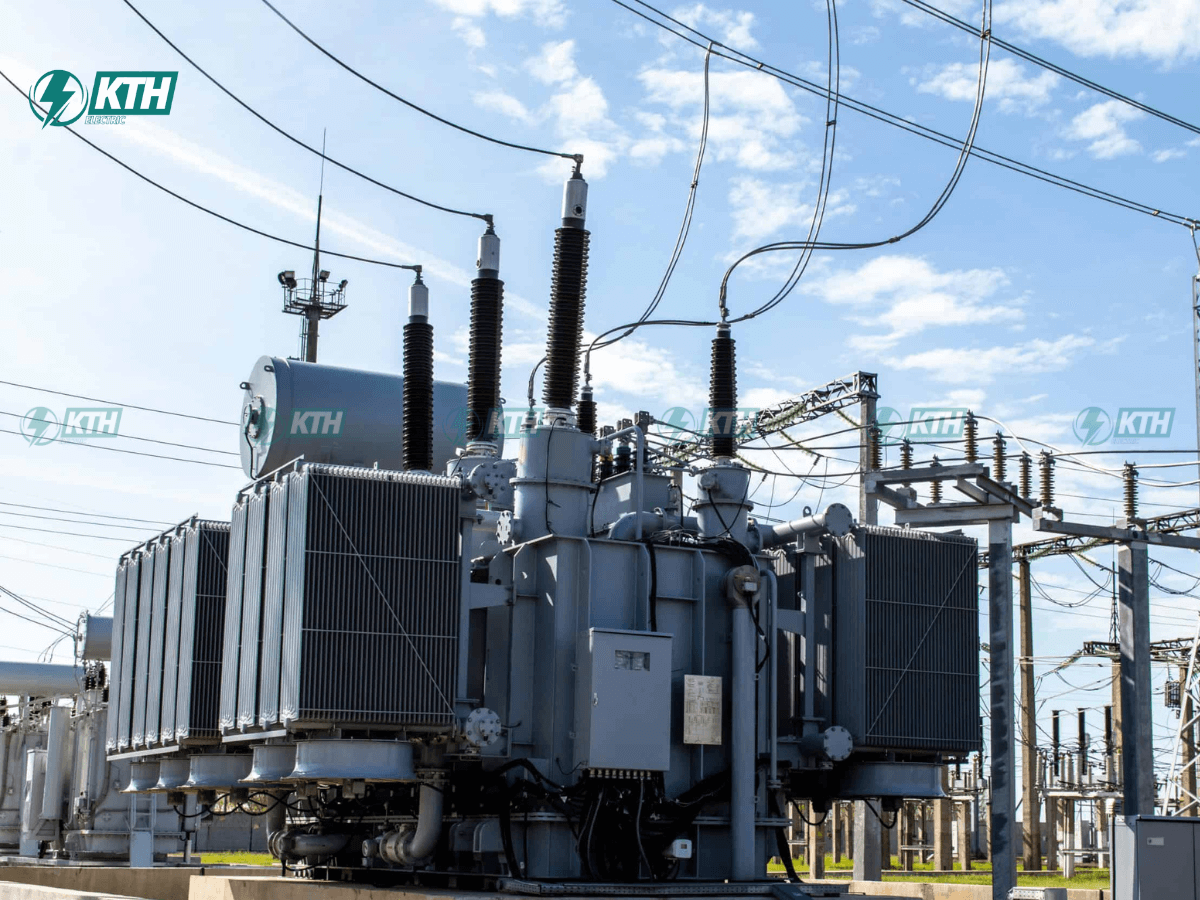

My core expertise includes: Power System Design, Substation Installation, and Heavy-Duty System Maintenance.