High Rupturing Capacity (HRC) Fuses: The Definitive Engineering Guide (2025)

Imagine a scenario in a heavy industrial plant: A 1000 kVA transformer feeds a main distribution board. Suddenly, a catastrophic short circuit occurs on the busbar. The fault current doesn’t just rise to 100 Amps or 200 Amps; within milliseconds, it spikes towards a potential peak of 50,000 Amps (50kA) or more.

At this level of energy, a standard rewireable fuse wouldn’t just melt—it would vaporize explosively, potentially destroying the low voltage electrical cabinet and injuring personnel. A standard circuit breaker might not be fast enough to stop the mechanical forces from warping the busway system.

“This is the domain of the High Rupturing Capacity (HRC) Fuse—the ‘special forces’ operative of circuit protection designed to handle massive fault currents silently, safely, and instantaneously.”

Whether you are a facility manager in Ho Chi Minh City or a design engineer, understanding the physics, construction, and selection of HRC fuses is not just about compliance with IEC standards—it is a matter of critical asset protection and life safety. This guide explores the engineering mechanics behind High Rupturing Capacity fuses, distinct from standard protective devices, and why they remain the gold standard for high-energy fault clearing.

I. The Concept: Definition & Fundamental Necessity

What is High Rupturing Capacity?

The term “High Rupturing Capacity” refers to the ability of a fuse to safely interrupt an extremely high short-circuit current (typically 80kA to 120kA) without destroying itself or the surrounding equipment.

While a standard household fuse might be rated to break a fault of 1kA or 2kA, an HRC fuse is engineered to handle fault currents ranging from 80kA to 120kA.

The Critical Distinction: Rated Current vs. Breaking Capacity

To understand HRC fuses, one must distinguish between two distinct values found on the nameplate:

Rated Current ($I_n$)

This is the normal current the fuse carries indefinitely without blowing (e.g., 100A, 200A).

Breaking Capacity

(Interrupting Rating): This is the maximum fault current the fuse can safely stop (e.g., 100,000A).

In modern industrial grids, the “Prospective Short Circuit Current” (PSCC) is rising due to larger transformers and lower impedance networks. Conducting a proper electrical system assessment is crucial to determine this value. If you install a device with a breaking capacity lower than the PSCC at that point in the network, you are essentially installing a potential bomb. The HRC fuse solves this by offering a rupture capacity that exceeds the highest possible fault levels in most low-voltage networks.

The Engineering Solution: $I^2t$ and Energy Limitation

The magic of the HRC fuse lies in its ability to limit the energy let-through. When a massive short circuit occurs, the current attempts to rise to its peak value (Prospective Peak). An HRC fuse operates so quickly (often in less than half a cycle, or <10ms) that it cuts off the current before it reaches that destructive peak.

This reduction in energy ($I^2t$) saves downstream cables from melting and protects switches from being blown apart by electromagnetic forces.

II. The Construction: Anatomy of an HRC Fuse

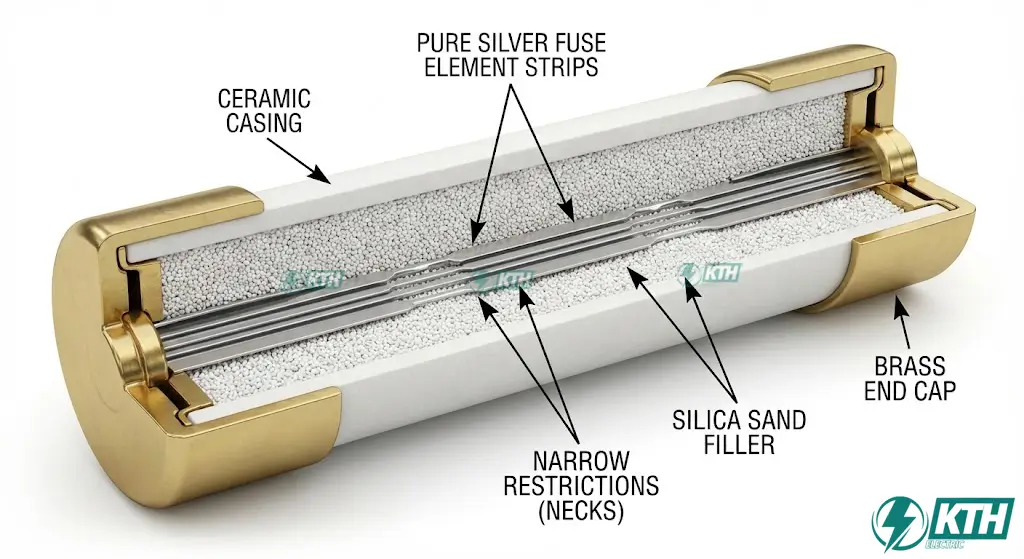

An HRC fuse looks simple on the outside—usually a ceramic barrel with metal tags—but the internal engineering is a masterclass in materials science. Every component plays a specific role in arc extinction.

1. The Body: Ceramic or Porcelain

The outer casing is never made of glass or ordinary plastic. It is crafted from high-grade steatite ceramic or thick porcelain.

Why? When the fuse blows, the internal pressure can rise significantly. The body must withstand this mechanical shock without bursting. Furthermore, ceramic has excellent thermal shock resistance, preventing it from cracking under the intense heat of the arc.

2. The Fuse Element: Silver (Ag)

Inside the body lies the heart of the device: the fuse element. Unlike simple wire, the HRC element is a precision-engineered strip, usually made of pure Silver (Ag) or copper.

Geometry: Deliberate “necks” or restrictions are designed to melt first, creating multiple small arcs.

The M-Effect: A blob of solder (lead/tin) creates a “Eutectic point,” allowing the high-melting-point silver to melt at roughly 230°C for overload protection.

3. Arc Quenching Medium: Silica Sand

The empty space inside is tightly packed with filling powder, typically pure Silica Sand (Quartz) or marble dust.

Function & Reaction: When the element vaporizes, the sand absorbs the heat and fuses with the silver vapor to form a high-resistance glass bead (fulgurite). This rapidly cools the arc and creates an insulating barrier.

4. Terminations

The end caps are typically manufactured from brass or copper and are often silver-plated to ensure low contact resistance with the fuse holder base.

III. The Mechanism: Working Principle & Arc Extinction

How does an HRC fuse stop a 50,000 Amp current?

“An HRC fuse operates on thermodynamics to cut off fault currents in less than 0.004 seconds (< 5ms). It utilizes a 3-phase process: Melting (Pre-arcing), Vaporization (Arcing), and Chemical Fusion (Extinction) to create a high-resistance glass barrier that physically blocks the current.”

How does an HRC fuse physically stop a 50,000 Amp current in 0.004 seconds? The operation can be broken down into three distinct phases.

Normal Operation & Pre-Arcing

Under normal load conditions, the $I^2R$ heat generated in the element is dissipated through the sand and the ceramic body to the surroundings. The element remains solid.

When a fault occurs, the current rises rapidly. The “Pre-arcing time” is the duration from the start of the fault until the element melts. At the restricted “necks” of the silver element, the current density is highest. These points reach the melting point of silver (960°C) almost instantly.

Arcing Time & Vaporization

Once the element melts at the necks, a gap is formed, and an electric arc is established across this gap. The silver doesn’t just melt; it vaporizes into a conductive plasma. This is the “Arcing time.”

In a standard fuse, this arc might sustain itself, burning the contacts. In an HRC fuse, the arc is immediately surrounded by the tightly packed, cool silica sand.

Chemical Fusion & Extinction

The intense heat of the arc (several thousand degrees Celsius) acts on the surrounding silica sand. The sand melts and chemically reacts with the silver vapor.

- The energy of the arc is consumed by the latent heat of fusion of the sand.

- The mixture forms a non-conductive, glass-like substance (fulgurite).

- This substance has very high electrical resistance.

As the resistance rises sharply, the current drops towards zero. The voltage required to maintain the arc increases beyond the system voltage, and the arc is extinguished. This entire process happens so fast that the fault current is “chopped” or “cut off” long before it reaches its natural sinusoidal peak.

IV. The Context: Types, Classes & IEC Specifications

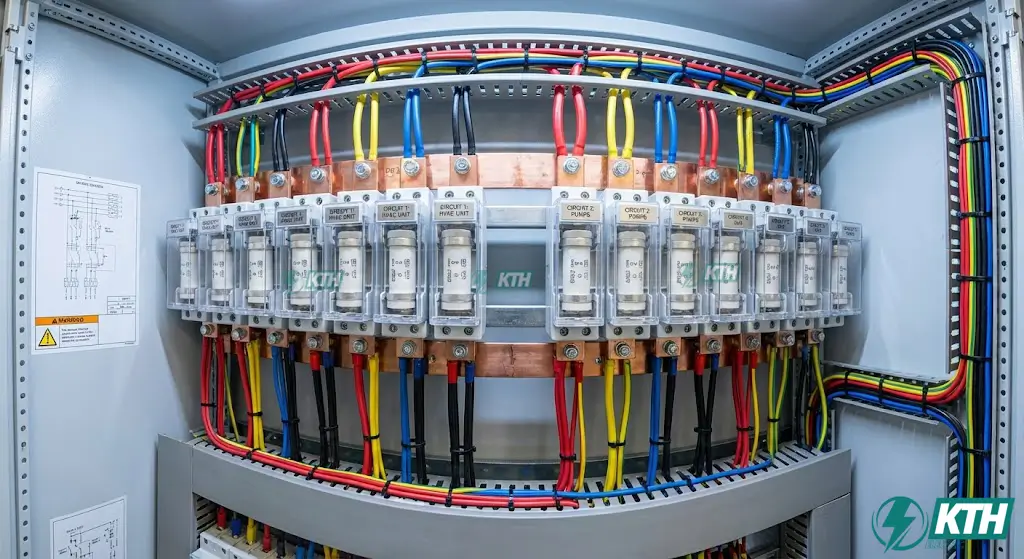

Not all HRC fuses are the same. Selecting the wrong “class” can lead to nuisance blowing (stopping production unnecessarily) or catastrophic failure (failing to protect a motor). At KTH Electric, we often see mismatched fuses in industrial panels. Here is how to decode the IEC 60269 markings:

1Utilization Categories (The Two-Letter Code)

You will see codes like gG, aM, or aR printed on the fuse link.

| Code | First Letter (Range) | Description & Application |

|---|---|---|

| g (General) | Full-range | Can interrupt everything from the lowest melting current up to its maximum breaking capacity (Overload + Short Circuit). |

| a (Back-up) | Partial-range | Designed ONLY to interrupt short circuits. Must be used with a separate overload relay. |

G (General/Cable)

Used for general line protection, distribution boards, and cables. (Most Common: gG).

M (Motor)

Designed specifically for motor circuits. Motors have high starting currents. An aM fuse is “slow” to blow at these surges but ultra-fast at short circuits. Essential for motor monitoring solutions.

R (Rectifier)

Ultra-rapid fuses (aR/gR) for protecting sensitive power electronics like SCRs in VFDs. Critical for proper inverter maintenance.

2Physical Construction Types

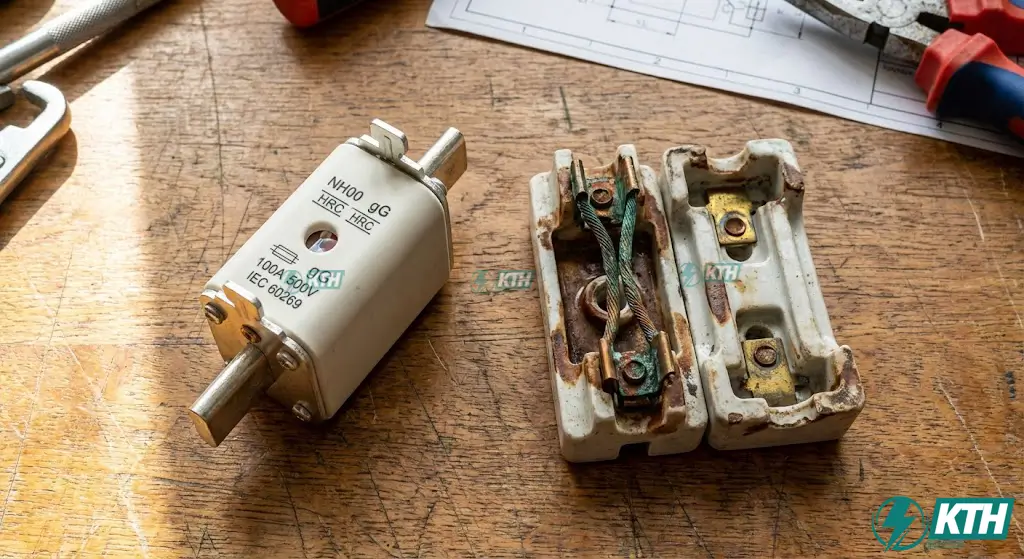

- NH / DIN Type (Blade Contact):The standard for European and modern Vietnamese industrial distribution panels. They feature square ceramic bodies with knife-blade contacts. Sizes range from NH00 to NH4.

- BS 88 (Bolted/Tag Type):Common in older systems or specific British-influenced designs. These bolt directly onto the busbar, ensuring excellent vibration resistance.

- Ferrule / Cylindrical (Cartridge):Small cylindrical fuses (10x38mm, 14x51mm) used in control circuits and multimeter protection.

- Liquid HRC Fuses:Designed specifically for High Voltage (HV) protection, typically for transformers in transformer stations. The fuse element is submerged in a liquid (often Carbon Tetrachloride). When the arc forms, the liquid vaporizes, expanding rapidly to extinguish the arc.

V. The Comparison: HRC Fuses vs. Alternatives

In modern electrical design, the debate often centers on “Fuse vs. Circuit Breaker.” While breakers offer the convenience of resetting, HRC fuses offer superior protection characteristics that mechanical devices cannot match.

1. HRC Fuses vs. Rewireable (Kit-Kat) Fuses

Breaking Capacity

Kit-Kat: 2kA – 4kA (Explosion risk).

HRC: 80kA – 120kA (Safe).

Aging & Calibration

Copper wire oxidizes, causing nuisance tripping. HRC silver elements are sealed and accurate for decades.

Speed

HRC uses current-limiting effects. Kit-Kats let full fault energy pass through.

2. HRC Fuses vs. Circuit Breakers (MCCB/MCB)

This is the critical engineering tradeoff.

| Feature | MCCB (Breaker) | HRC Fuse |

|---|---|---|

| Fault Clearing Time | 20-30 ms (Mechanical inertia) | < 5 ms (Sub-cycle) |

| Reliability | Moving parts may seize | “Fit and Forget” (No moving parts) |

| Discrimination | Complex coordination required (See recloser) | Easy (1.6:1 Ratio) |

VI. The Application: Selection & Sizing Methodology

Selecting the correct HRC fuse is not as simple as matching the Amperage. As engineers, we must follow a rigorous 4-step process.

Voltage Rating ($U_n$)

The rated voltage of the fuse must be greater than or equal to the phase-to-phase voltage of the system.

Current Rating ($I_n$) and Load Type

- Resistive Loads: Select $I_n \ge I_{load}$.

- Inductive Loads (Motors): Motors draw 6-8x current at start. Using a standard gG fuse? It will blow.

Solution: Use an aM (Motor Rated) fuse, or oversize gG (150-200%), ensuring the downstream Thermal Overload Relay protects against small overloads.

Prospective Fault Current

Calculate the fault level. If PSCC is 60kA, a 50kA fuse is unsafe. Standard HRC fuses (80kA/120kA) usually cover this, but verify during electrical system maintenance service.

Discrimination (Selectivity)

Rule of Thumb: Upstream Rating $\ge$ 1.6 $\times$ Downstream Rating.

Example: 100A downstream needs at least 160A upstream.

VII. The Content: Practical Maintenance & Troubleshooting

👁️ Visual Inspection

Check the Red Indicator Pin (Striker) on the top/front face.

- Flush: Status Good.

- Popped Out: Status Blown.

⚡ Electrical Testing

Use a multimeter in Resistance ($\Omega$) mode:

- 0 $\Omega$ (Beep): Good.

- Infinite / OL: Blown.

🔥 Thermal Runaway (The #1 Killer)

Often, a fuse blows not because of a fault, but because of loose connections generating heat ($I^2R$). This is invisible to the naked eye.

Action: It is highly recommended to perform a thermal scan of the electrical cabinet to identify these hot spots before failure.

⚠️ Safety Protocols

Always use a Fuse Puller Handle. Follow LOTO (Lockout-Tagout). Never replace a fuse under load to prevent arc flash burns.

VIII. Conclusion & Key Takeaways

The High Rupturing Capacity (HRC) fuse remains the bedrock of electrical safety. While circuit breakers offer convenience, they cannot match the fault-clearing speed and breaking capacity of an HRC fuse during catastrophic events.

- Safety: HRC fuses protect personnel and transformer assets by limiting fault energy.

- Reliability: Non-deteriorating silver elements ensure accurate protection for decades.

- Selection: Distinguish between gG and aM curves to avoid nuisance tripping.

- Replacement: Always replace with the exact rating. Never bypass with wire.

“The HRC fuse is the silent sentinel—standing guard against the massive power of the grid, ready to sacrifice itself in milliseconds to save your facility.”