How to Wire a NEMA 5-30 Receptacle (30A – 125V): The Complete Guide

Category: Electrical Installation

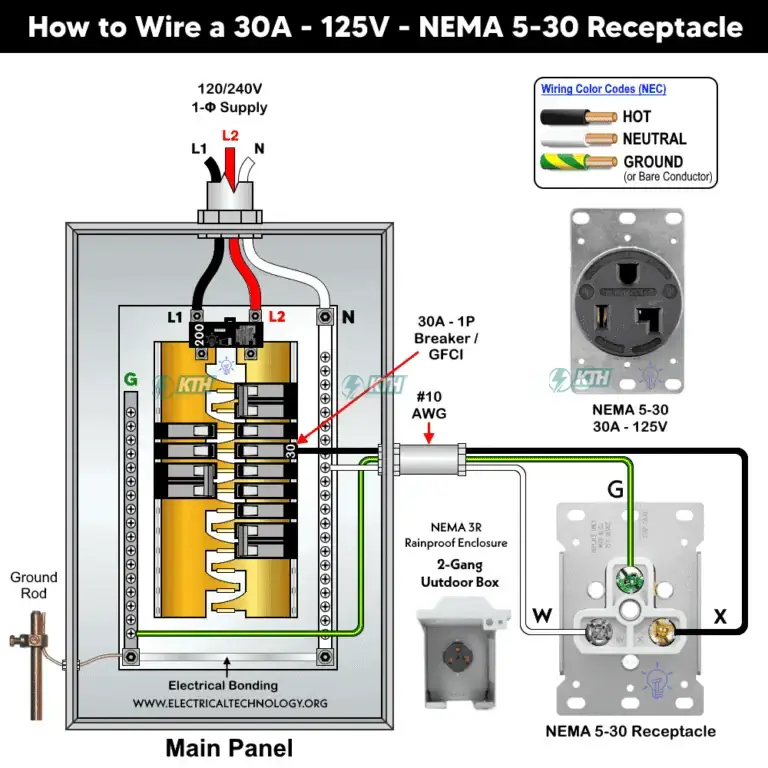

Installing a high-amperage outlet differs significantly from replacing a standard household plug. The NEMA 5-30R is a specialized, heavy-duty receptacle designed to deliver 30 Amps at 125 Volts. It is typically found in industrial settings, workshops for heavy power tools, or specific large 120V heaters.

Because this circuit handles double the current of a standard outlet, mistakes in wiring—such as loose connections or undersized wires—can lead to immediate overheating and fire hazards. This guide breaks down the NEC-compliant process to ensure a safe and durable installation.

How do you wire a 30 Amp 125 Volt plug?

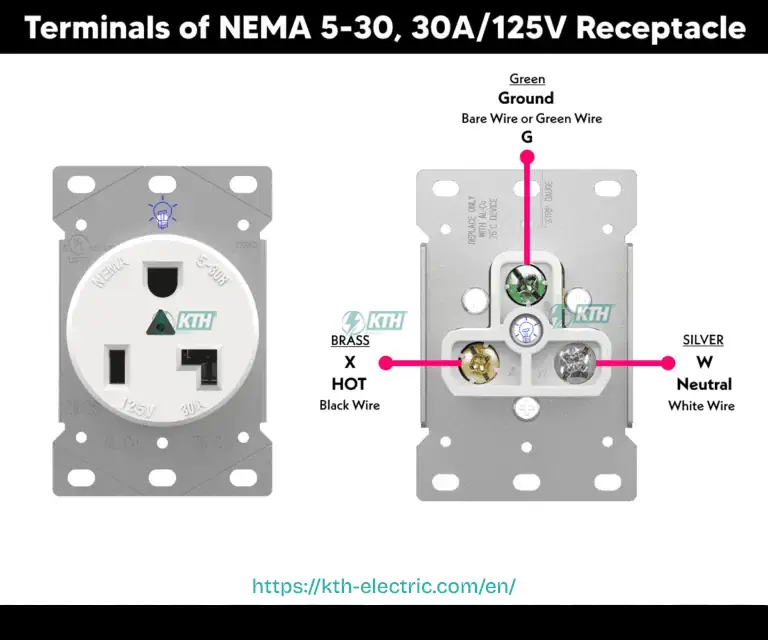

To wire a NEMA 5-30R (30 Amp, 125 Volt) receptacle, use #10 AWG wire, connecting the Hot (black) wire to the brass screw, the Neutral (white) wire to the silver screw, and the Ground (bare or green) wire to the green screw. Ensure clockwise loops and tight connections to prevent exposed copper.

Source: TheRunningHomestead (YouTube)

Provides a visual guide on how to wire a 30 amp NEMA 5-30R receptacle step-by-step.

Source: Ultimate DIYer (YouTube)

Watch to see how to make the perfect wire bend for heavy gauge #10 wire.

NEMA Types Confusion: This is the single most common mistake. Don’t confuse the NEMA 5-30R (Straight blades, 125V Industrial) with the NEMA TT-30 (Angled blades, 120V RV Standard).

While both are 30 Amp and 120V, their physical configurations are different. Forcing a TT-30 RV plug into a 5-30 receptacle (or vice versa) using makeshift adapters violates safety codes and can damage plugs.

Additionally, never confuse this with a NEMA 6-30 (240V). Connecting a 120V device to a 240V circuit will instantly destroy equipment.

1. Materials & Tools Checklist

To ensure a professional-grade installation, using the correct materials is non-negotiable. #10 AWG wire is stiff and difficult to manipulate, so having the right tools makes the job significantly easier.

Required Materials

- NEMA 5-30R Receptacle: Ensure it is marked “125V” and “30A”.

- #10 AWG Copper Wire: You need Black (Hot), White (Neutral), and Bare/Green (Ground). Do not use Aluminum wire without antioxidant paste and rated terminals.

- Electrical Box: A Deep 2-Gang box is highly recommended to accommodate the stiff #10 wires and heat dissipation.

- Faceplate: A specific cover plate with the correct diameter hole (usually 2.125 inches).

Essential Tools

- Wire Strippers: Must have a specific notch for #10 AWG to avoid nicking the conductor.

- Torque Screwdriver: Critical for tightening terminals to manufacturer specs (usually 25 lb-in) to prevent “cold flow” and arcing.

- Voltage Tester: Non-contact type for initial check, Multimeter for final verification.

- Needle-nose Pliers: Essential for bending heavy gauge wire loops.

| Specification | Requirement | Notes |

|---|---|---|

| Wire Gauge | #10 AWG Copper | Mandatory per NEC Table 310.16. |

| Voltage | 120V – 125V AC | Single Phase, 60Hz. |

| Breaker | 30A Single-Pole | Use GFCI Breaker for garages/outdoors (NEC 210.8). |

| Torque | 25 lb-in (Typical) | Check device label for exact specs. |

2. Detailed Wiring Steps (NEC Compliant)

Follow this 5-step protocol to ensure a safe connection. Take your time bending the wires, as #10 AWG requires force and precision.

Safety First (Lockout/Tagout)

Turn off the power at the main circuit breaker panel. Place a piece of tape over the breaker to prevent others from turning it on. Verify the power is truly off using a non-contact voltage tester at the box location.

Prepare Wires & Form Hooks

Strip about 1/2 to 3/4 inch of insulation from the end of each wire. Be careful not to nick the copper, as this creates a weak point for heat buildup.

Using needle-nose pliers, bend the stripped ends into a “J” hook shape. Ensure the open end of the hook faces to the right (clockwise). This is critical: as you tighten the screw clockwise, it will pull the loop tighter around the shaft. If you loop it counter-clockwise, the wire will be pushed out as you tighten.

Connect the Wires (Pinout Verification)

Connect the wires in the following order to maximize safety:

- 1. Ground First: Attach the bare copper or green wire to the green hexagonal screw. This ensures the frame is grounded before any power connection is made.

- 2. Neutral Second: Attach the white (neutral) wire to the silver screw (connected to the longer slot).

- 3. Hot Last: Attach the black (hot) wire to the brass screw (connected to the shorter slot).

Torque & Secure

This step is often skipped by amateurs but is required by code. Use a torque screwdriver to tighten terminals to the manufacturer’s specification (usually 25-30 lb-in).

Loose connections cause arcing and fires. Ensure no bare copper extends beyond the plastic housing of the receptacle. Carefully fold the stiff wires into the electrical box (Z-fold method works best) and mount the device.

Restore Power & Test

Turn the breaker back on. Do not just plug equipment in immediately. Use a Multimeter set to AC Voltage to verify:

- Hot to Neutral: ~120V

- Hot to Ground: ~120V

- Neutral to Ground: 0V